Home >> Granulators >> GC Series Granulator

GC Series Granulator

Typical applications

- Plastics – Mouldings, Profiles, Films etc.

- Rubber – Tyre Rubber, Relaim Rubber Products.

- Paper & Cardboard – Confidential Documents, Production Waste, Packaging Materials..

- Copper Cable – Household, Telecoms and Industrial Cables including S.W.A.

- Textiles – Carpet (Rolls & Tiles).

- Foam – Production Waste.

Description

GC Series Granulators are high-speed granulation machines designed especially for the efficient size reduction of various materials in a single pass. These machines are ideal for processing a multitude of materials including plastics, rubber, copper cable and organics amongst others.

GC Series Granulator features

- Compact design minimizes on-site space requirements.

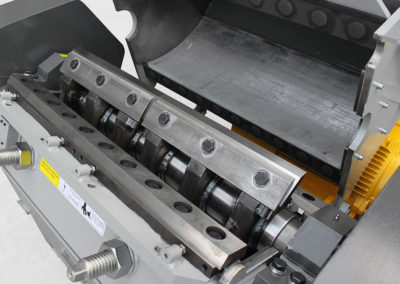

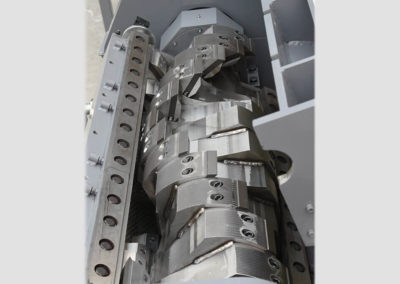

- Inclined, split cutting chamber design.

- Oversized, outboard spherical rotor bearings – prevents bearing damage due to product migration.

- Precision machined rotors (Forward set V-Rotor as standard).

- Replaceable wear plates at either end of the rotor shaft.

- Standard machines are prepared for air extraction.

- Stand Alone Electrical Control Panel – using quality Schneider components and Siemens PLC’s.

- Tested, Approved and Certified to the applicable CE safety standards.

Enquire about the GC-Series Granulator

GC Series specifications

+ GC600T - GC800T

| Model | GC600T | GC800 | GC800T |

| Dimension (L x W x H) (mm) | 1380 × 1170 × 2200 | 1380 × 1370 × 2200 | 1580 × 1440 × 2300 |

| Hopper Opening (L x H) (mm) | 560 × 615 | 760 × 615 | 760 × 615 |

| Rotation Diameter (mm) | Φ320 | Φ320 | Φ420 |

| Operation Length (mm) | 600 | 800 | 800 |

| Rotation Speed (RPM) | 580 | 580 | 580 |

| Screen Size(mm) | Φ12 | Φ12 | Φ12 |

| Number of Rotor Knives | 3×2 | 3×2 | 3×2 |

| Number of Counter Knives | 2×1 | 2×1 | 2×1 |

| Main Drive (kW) | 22 | 30 | 37 |

| Weight(kg) | Approx 1500 | Approx 1800 | Approx 3000 |