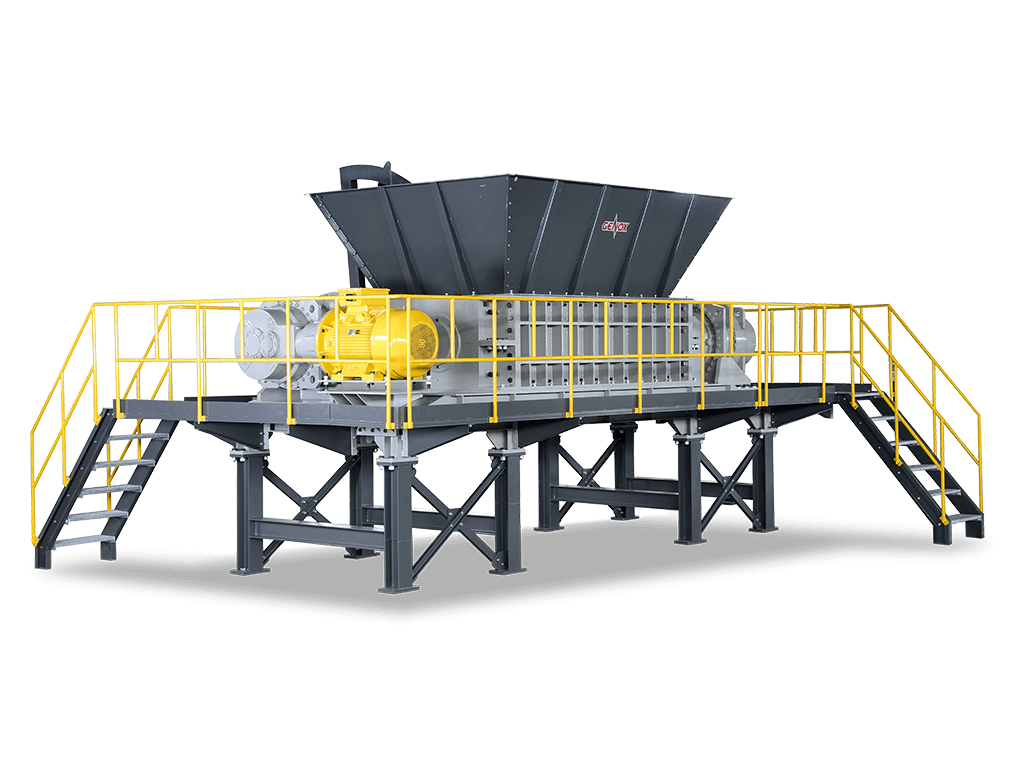

X Series Twin Shaft Shredder

Typical applications

- Tyres – Car, Truck and Off The Road – Earthmovers.

- Steel – Car Body Shells, Sheet Scrap, Drums etc.

- Electronic Scrap – WEEE Directive Materials.

- Wood/Timber – Pallets, C&D Waste etc.

- Aluminum – Castings, Profiles, etc.

- Bulky Waste – Mixed Household, Commercial, Pulper Waste from Paper Industry etc.

Description

X Series Twin Shaft Shredders are extremely high torque, high throughput, rotating shear type size reduction machines often used for pre-shredding of large volume or high strength materials which may contain contamination. The unique modular split chamber design, provides excellent access to key components which reduce maintenance downtime and service costs. X Series Twin Shaft Shredders are supplied and installed by Genox UK.

X Series Shredder Features

- Slow Speed High Torque Shredding Principle.

- Low Dust and Low Noise Operation.

- Rugged Low Maintenance Design.

- Shock Absorbing Gearbox Mounting Arrangement reduces

- Stress on Drive Components.

- Strong Blades manufactured from high quality steels are suitable for shredding tough materials.

- Two Piece Split Bearing Housing Arrangement enables quick access to bearings and rotor.

- Advanced Adjustable Sealing System prevents product migration and ensures long bearing service life.

- Stand Alone Electrical Control Panel with Siemens PLC Control System.

- Tested, Approved and Certified to the applicable CE safety standards.

Enquire about the X-Series Shredder

Specifications – X1000-X2500

| Model | X1000 | X1300 | X1600 | X1500 | X1800 | X2200 | X2500 | |

| Main Drive(kw) | 30+30 | 30+30 | 30+30 | 55+55 | 55+55 | 55+55 | 55+55 | |

| 37+37 | 37+37 | 37+37 | 75+75 | 75+75 | 75+75 | 75+75 | ||

| 45+45 | 45+45 | 45+45 | 90+90 | 90+90 | 90+90 | 90+90 | ||

| 55+55 | 55+55 | 55+55 | 110+110 | 110+110 | 110+110 | 110+110 | ||

| Rotation Diameter(Φmm) | 515 | 515 | 515 | 750 | 750 | 750 | 750 | |

| Shredding width(mm) | 1000 | 1300 | 1600 | 1500 | 1800 | 2200 | 2500 | |

| Rotation Speed(rpm) | 4.2-12 | 4.2-12 | 4.2-12 | 4.2-12 | 4.2-12 | 4.2-12 | 4.2-12 | |

| 4.2-12 | 4.2-12 | 4.2-12 | 4.2-12 | 4.2-12 | 4.2-12 | 4.2-12 | ||

| 5.4-12 | 5.4-12 | 5.4-12 | 5.4-12 | 5.4-12 | 5.4-12 | 5.4-12 | ||

| 6-12 | 6-12 | 6-12 | 6-12 | 6-12 | 6-12 | 6-12 | ||

| Center distance(mm) | 400 | 400 | 400 | 610 | 610 | 610 | 610 | |

| Number of Blades | 40thickness | 25 | 32 | 40 | 37 | 45 | / | / |

| 50thickness | 20 | 26 | 32 | 30 | 36 | 44 | 50 | |

| 75thickness | 13 | 17 | 21 | 20 | 24 | 29 | 33 | |

| 100thickness | / | / | / | 15 | 18 | 22 | 25 | |

| The quantity of blade hocks | Standard rotor | 1/2/3/6 | 1/2/3/6 | 1/2/3/6 | 1/2/3/6 | 1/2/3/6 | 1/2/3/6 | 1/2/3/6 |

| K type rotor | 1/2/3/6 | 1/2/3/6 | 1/2/3/6 | 1/2/3/6 | 1/2/3/6 | 1/2/3/6 | 1/2/3/6 | |

| D type rotor | 8 | 8 | 8 | 12 | 12 | 12 | 12 | |

| Dimension | L | 4592 | 4892 | 5150 | 6340 | 6993 | 7110 | 7986 |

| W | 2210 | 2210 | 2270 | 2610 | 3045 | 3342 | 3284 | |

| H | 2600 | 2600 | 2600 | 4000 | 4000 | 4000 | 3760 | |

| A | 1765 | 2065 | 2365 | 2705 | 3005 | 3405 | 3560 | |

| B | 1620 | 1620 | 1620 | 2445 | 2445 | 2445 | 2466 | |

| C | 973 | 973 | 973 | 1545 | 1545 | 1545 | 1380 | |

| D | 948 | 948 | 948 | 1550 | 1550 | 1550 | 1650 | |

| E | 1590 | 1890 | 2190 | 1850 | 2148 | 3125 | 2820 | |

| Weight | 8600 | 10300 | 11400 | 27700 | 32450 | 38600 | 46320 |